Cost Reduction in Hot Rolling- Preventing Rejections & Reducing Fuel Consumption by the Use of Protective Coatings

- Home

- Cost Reduction in Hot Rolling- Preventing Rejections & Reducing Fuel Consumption by the Use of Protective Coatings

Cost Reduction in Hot Rolling- Preventing Rejections &

Reducing Fuel Consumption by the Use of Protective Coatings

By

S. P. Shenoy

M.Tech. (Met. Engg.), CEO,

Steel Plant Specialities LLP, India.

www.steelplantspecialities.com

Abstract

Protective coatings play a major role in increasing productivity and reducing costs in metal forming processes like hot rolling and heat treatment. Most of these coatings are pioneered in India by an experienced metallurgist from the Indian Institute of Technology. This technical paper presents details and successful case studies of three such protective coatings:

1. Oxidation and decarburisation at high temperatures are caused during heating of billets or ingots for hot rolling and during heat treatment of rolled products. Scaling leads to enormous losses by way of rejections of produce, reduced yield and increase in expensive, time-consuming operations like acid pickling, grinding etc. Billets are often subjected to excessive heat in furnaces due to unplanned downtime of rolling mill. In such cases, high oxidation and resultant decarburisation may lead to rejection of entire heat. The need to control decarburisation and scaling is gaining much importance, especially in the case of expensive grades of steel and critical hot rolled products like rail steel and spring steel. Protective anti-scale coatings and decarburisation control coatings can be used to substantially reduce oxidation and control decarburisation during billet re-heating for hot rolling and heat treatment of rolled products. Recent developments in these coatings have made coating technique viable for most grades of steel.

PROTECTIVE COATING 1: TO PREVENT SCALING AND

CONTROL DECARBURISATION

Introduction

In hot rolling and even hot forging of Steels and alloy steels, the major factor accounting for reduced yield is ‘burning loss’ or ‘scale loss’ or ‘mill scale’ caused due to Oxidation. Oxidation and decarburization of steel take place when billets or ingots are heated in a billet re-heating furnace, in the presence of air or products of combustion. Apart from burning loss of between 1.5% up to 4%, oxidation leads to numerous other problems like scale pit marks, bad quality surface finish of metal, rejections, cumbersome task of removal of mill scale and increased expensive operations like grinding, acid pickling, etc.

This article introduces a practical technique pioneered by an experienced Metallurgist from the Indian Institute of Technology (I.I.T.). The technique enables any kind of steel to be heated by substantially minimizing the problem of oxidation.

UNDERSTANDING BURNING LOSS DUE TO OXIDATION

For the purpose of hot rolling, when billets or ingots are heated in an open furnace in the presence of air or products of combustion, the surface phenomena of oxidation takes place. Oxidation causes immediate corrosion of steel at high temperature and creates a layer of metal-oxide, or mill scale, on the surface of the billets or ingots. Decarburisation is a simultaneous reaction that takes place along with oxidation. However, this decarburization is limited to certain grades of steel only.

OXIDATION

Oxidation of steel is caused by oxygen, carbon dioxide and/or water-vapour. The general reactions are given below:

| Chemical Reactions | ||

|---|---|---|

| O2 + 2 Fe | ⇌ | 2 FeO |

| O2 + 4 FeO | ⇌ | 2 Fe2O3 |

| CO2 + Fe | ⇌ | CO + FeO |

| CO2 + 3 FeO | ⇌ | Fe3O4 + CO |

Oxidation of steel may range from a tight, adherent straw-coloured film that forms at a temperature of about 180 C to a loose, blue-black oxide scale that forms at temperature above about 450 C with resultant loss of metal or reduced yield.

HARMFUL EFFECTS OF OXIDATION

Oxidation leads to loss of dimensions and material as extra material allowance needs to be kept for scaling. Often, surface quality is deteriorated due to scale-pitting. This is especially true in the case of Nickel bearing grades of steel. Throughout the industry, this burning loss or scale loss is simply treated as wastage and not many practical solutions are available to stop or reduce this wastage. Problems like thick adherent scaling or scale pit marks or decarburization are dealt by manually grinding off the scale or decarburized layer after the hot forging or hot rolling process.

PREVENTING OR REDUCING BURNING LOSS DUE TO OXIDATION

Prevention or substantial reduction of oxidation is not only better than cure, it is profitable too. However, most of the available solutions pose a number of practical difficulties. Capital-intensive special furnaces and availability of human resource for using these high-end furnaces is a major issue. Many small hot rolling Organizations cannot afford these solutions. Yet they are under mounting pressure to increase yield and reduce costs. Use of protective anti-scale coating has proven to be a logical solution to the problem of scaling and decarburization in open die hot forging and hot rolling.

CHARACTERISTICS OF PROTECTIVE COATING AND ITS USE:

Use of protective coating has been found beneficial and cost-effective. An anti-scale coating is applied on billets / ingots to be heated, before charging them into furnace. This anti-scale protective coating acts as a barrier between oxygen and metal. Care is taken to apply a uniform, impervious layer of coating on the billet to be heated. Coating ensures substantial reduction of oxidation, and thereby reduction in burning loss or mill scale. Anti-scale coating also reduces decarburization on billets during hot rolling operations. Heat transfer from heating media to metal is not affected due to anti-scale protective coating.

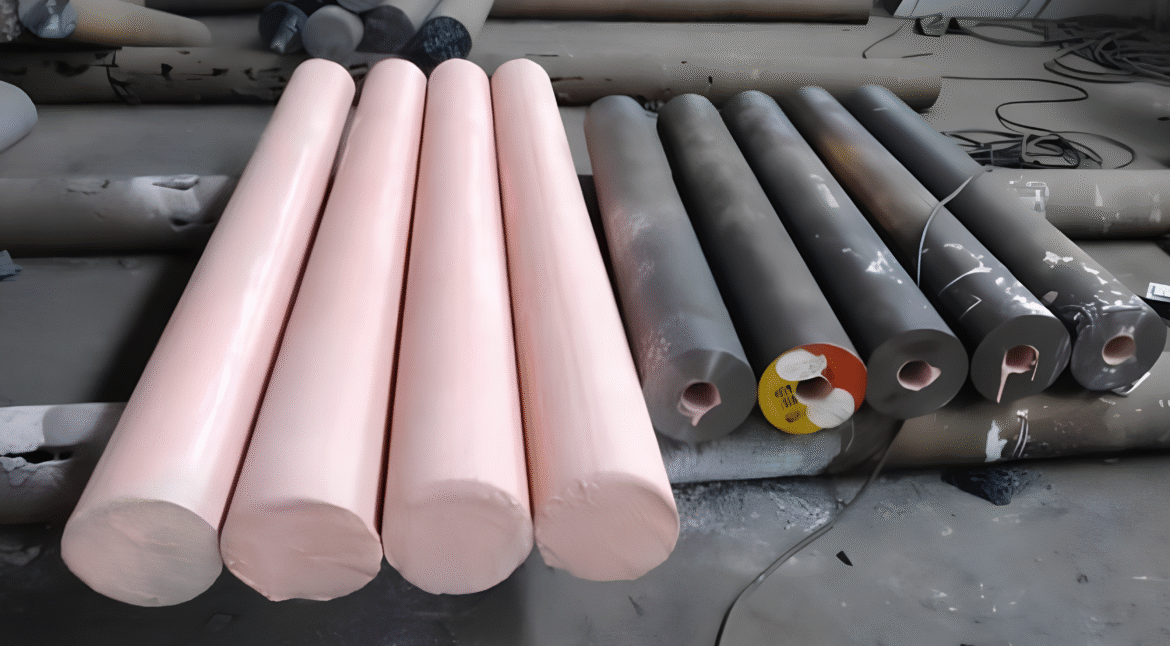

No reaction with steel surface, no release of toxic fumes during use or hot forging or storage, non-hazardous and economical implementation are other required characteristics of the coating. Adjoining photographs shows coated stainless steel ingot before being charging into furnace and coated billets before being charged into billet re-heating furnace. Coating may be applied by brushing, spraying or dipping

INCREASING YIELD BY THE USE OF PROTECTIVE ANTI-SCALE COATING; INDUSTRIAL CASE STUDIES AND SUCCESS STORIES.

Due to reduction in oxidation by the use of protective anti-scale coating during hot rolling, the scale thickness is considerably reduced. Adjoining photographs are of mill scale that were generated on billets during re-heating for hot rolling with and without using protective anti-scale coating:

Thin, loose scale is observed on billets when protective coating is used.

White layer of coating residue is observed on scale.

This indicates efficacy of coating.

Thick adherent scale is observed on billets when coating is not used.

Thickness of mill scale fallen off both, coated and not coated billets, is measured using digital vernier calliper. As shown in image, scale of much lower thickness of 0.717 mm is generated on billets that were protected using anti-scale coating. In comparison, billets that were not protected and were charged in the same batch of heating have shown thicker and more adherent scale of 1.667 mm.

Total reduction in scale: 0.95mm.

Percentage reduction in mill scale loss due to use of protective anti-scale coating: 56.98%

On an average, approximately 70% reduction in mill scale is usually achieved by the use of anti-scale protective coating in open die hot forging and hot rolling of stainless steel. This amounts to lucrative savings and increased yield.

Another report of a number of mild-steel billets hot rolled without coating in comparison with hot rolling similar billets with single coating and double coating of anti-scale protection is provided below:

| Sr No | Billet wt before coating in Kg | Billet wt After Heating in Kg | Scale Difference in Kg | 3 billet wt before coating in Kg | 3 billet wt after heating in Kg | Coating Type |

|---|---|---|---|---|---|---|

| 1 | 47.720 | 47.330 | 0.390 | With Coating | ||

| 2 | 47.010 | 46.660 | 0.350 | With Coating | ||

| 3 | 46.510 | 46.110 | 0.400 | 141.240 (Sr No 1,2,3) | 140.100 (Sr No 1,2,3) | With Coating |

| 4 | 47.720 | 46.900 | 0.820 | Without Coating | ||

| 5 | 46.930 | 46.260 | 0.670 | Without Coating | ||

| 6 | 46.450 | 45.800 | 0.650 | 141.100 | 138.960 (Sr. No 4,5,6) | Without Coating |

- Scale loss of 2.140 kgs. was observed on billets without coating. ·

- Scale loss of 1.140 kgs. was observed on billets with double layer of protective anti-scale coating.

- Percentage reduction in mill scale loss due to use of protective anti-scale coating: 47.00%

Problem: Very adherent scale on Nickel steel causes pit-marks and rejections of forgings.

Not Coated Billets.

Solution: Use ESPON anti-scale protective coating on billets. Substantially reduce scaling. Reduce Rejections. Increase yield.

ESPON Coated Billets.

A NUMBER OF OTHER BENEFITS BY THE USE OF PROTECTIVE ANTI-SCALE COATINGS IN HOT ROLLING AND HOT FORGING:

1. REDUCTION IN PEELING, ACID PICKLING TIME OF HOT ROLLED PRODUCTS:

Operations like grinding, acid pickling, etc. do not add value, are expensive and time consuming procedures. These operations are necessary to remove adherent scaling from the hot rolled billets. Time required for operations like shot blasting, grinding, acid pickling, etc. can be substantially reduced if protective anti scale coating is applied on components before heat treatment. Aesthetic appeal of components is automatically enhanced without much effort as scaling is either prevented or reduced by the use of anti-oxidation protective coating.

2. REDUCED DECARBURIZATION DURING HOT ROLLING AND HOT FORGING :

Certain grades like spring steels, ball bearing steel and rail steel are susceptible to decarburisation. During hot rolling of these special grades, decarburization needs to be consistently maintained to the required specification. However, due to unforeseen conditions like mill breakdown and unplanned downtime, billets remain in the furnace for longer time than usual. Also, when the plant is closed for weekly holiday, furnace is shut off abruptly, subjecting the billets to prolonged heating inside the furnace. If billets are not coated, it becomes difficult to guarantee the consistency in the decarburization level. Use of protective coatings on billets before charging them into the re-heating furnace enables to maintain the decarburization level consistently. This enables the hot rolling mill to guarantee their customers that decarburization level will always be less than the upper control limit.

Reduced decarburization on automobile leaf springs leads to increased fatigue strength of the leaf springs and greater reliability. Leaf springs heated after applying protective coating show substantially reduced decarburization and scaling.

3. PREVENTING CRACKING DURING HOT ROLLING AND HOT FORGING:

Micro cracks formation is a common occurrence during casting of billets. 20MnCr5 and a range of such sensitive grades of steel are susceptible to cracks. There are different types of surface defects, with many of them having to do with the poor quality of steel during continuous casting. Other important stages following continuous casting are reheating and hot rolling. There is always a chance that surface defects after casting are either very small or not detected. These defects will extend and show up in the later stages, i.e., during reheating or rolling.

Depending on the depth of surface irregularities on the surface of heavy plates, they might be rejected, which is considered as a major economic loss for a plant. Alternatively, a heavy plate containing surface defects might be downgraded due to poor surface quality and poor surface appearance. Thus, one of the most important objectives of a hot rolling plant is to minimize surface defects. Minor cracks formed during casting of billets are further intensified during hot rolling and lead to major cracking of hot rolled products. Similarly, micro cracks formed during hot forging propagate further during heat treatment. In the case of open-die forging, ingots too develop cracks. These ingots are either rejected or the cracks are removed by gouging when ingots are red hot. The ingots are then re-heated to forging temperature for open-die forging. Hence, even if ingots are salvaged, there is substantial loss of fuel for re-heating of ingots and loss of time for forging production.

In all the mentioned cases, it may lead to rejection of hot rolled or hot forged products. ESPON protective coatings are used to prevent cracking of hot rolled and hot forged products. The coating prevents intensifying of micro cracks that are formed during preliminary stages. Hence, billets must be protected with coating before re-heating for hot rolling. Ingots and forged parts are protected with coating during heating for forging and during heat treatment to prevent cracking and rejections during hot rolling and hot forging.

4. IMPROVING SURFACE FINISH OF HOT ROLLED COMPONENTS AND PREVENTING WELDING OF BILLETS DURING HEATING:

During hot rolling of special grades of steel like Nickel (Ni) and 416 Stainless Steel containing high sulphur content, mill scale formation is greatly increased. Surface finish of hot rolled product may be compromised due to scale pits and rolled-in scale. Occasionally, due to heavy adherent scale, problem of roll skid is also encountered. Subsequent grinding operations are increased due to excessive mill scale. Protecting the billets with ESPON anti-scale protective coating before charging them into the re-heating furnace ensures remarkable reduction in oxidation and mill scale. Coating the billets before charging them into the reheating furnace enables to achieve good surface finish of the hot rolled products, free from scale pits and rolled-in scale. Reduction of scale also has a positive effect on roll life as adherent scale is known to cause serrations, and compromise roll life. During re-heating of billets for hot rolling and also during induction heating of billets for hot forging, sometimes, billets get welded together. This leads to unproductive process of separating the welded billets and downtime. Welding of billets during hot rolling and hot forging can be prevented by applying protective coating on billets before charging them into the furnace.

5. REDUCED FURNACE DOWNTIME FOR SCALE REMOVAL AND HEARTH REPAIR:

Scales fallen in furnace have a tendency to damage the furnace floors or hearth. In many rolling mills, furnace downtime is undergone only to remove scale from furnaces and to repair the hearth. Removal of scale from rolling machinery and all other locations of the rolling mill or forge shop is also a cost. Hence, substantial reduction in scale will automatically reduce costs involved in disposal of scale. Furnace downtime is reduced and it has an overall positive impact on productivity of the hot rolling and hot forging process.

Photograph shows not coated billet on conveyor, discharged from furnace and passed through water de-scaler. As thick, adherent scale was formed, water de- scaling has not been effective. Adherent scale is observed on the top surface and some adherent scale on the left side surface.

Photograph shows anti-scale coated billet on conveyor, discharged from furnace and passed through water de-scaler. Minimum, loose scale was formed that has completely fallen off during water de-scaling.

This proves that scale loss is reduced. Ease of rolling operation and reduced scale deposits on the rolling mill machinery are ensured.

6. IMPROVING SURFACE FINISH OF SEAMLESS TUBES OD AND ID:

In the manufacture of seamless tubes, machined hollow ingots are used in many Organizations, especially in Poland. It becomes a necessity to protect the surface by protective coating when the ingot is reheated. This ensures better surface finish of the seamless pipe. If scaling occurs in the internal diameter, it is almost impossible to remove it. Hence, wherever practical, ESPON anti-scale coatings are used to protect the internal diameter of the seamless tubes. In this way, both the outer and inner diameter of seamless tubes can be protected from scaling

The picture above shows billets protected with anti-scale coating, before heating for seamless tube making by mandrel-piercing process. This protects the OD.

On the right are seamless tubes with coating in ID of the tubes to protect from scaling during heat treatment

PROTECTIVE COATING 2: REFRACTORY COATING TO INCREASE REFRACTORY LINING LIFE, REDUCING FUEL CONSUMPTION

IN FURNACE OPERATIONS

Hot rolling involves plastic deformation of heated metals and alloys into flat products (slabs, plates) or long products (wire rods, angles, channels, I sections, TMT bars, etc.). In this important metal forming operation, refractory and fuel for the reheating furnace (such as furnace oil, pulverized coal or gas) are the major costs. Any process or technique to reduce these costs will automatically improve the profitability of the rolling mill.

The following problems are encountered in the case of refractories:

1) Thermal shock cracking:

Thermal shock is unavoidable in furnace operation; however, much care may be taken. Due to thermal shock, cracks are initiated in the refractory lining. Energy leaks through these cracks. This loss may be as high as 33% of the total energy consumption. This is the reason why fuel consumption is observed to be more after a time gap of say, six months from the date of relining the furnace, for the same level of production.

2) Low Emissivity:

Refractory lining has a low emissivity of 0.2 and hence hampers furnace efficiency. Improving this value to 0.5 or more will lead to fuel saving.

3) Corrosive Action:

Furnace oil contains sulphur dioxide and vanadium pent oxide. These compounds corrode the refractory lining.

4) Vicious sand blasting effect:

The flame impinging on the refractory lining has a vicious effect of sand blasting.

5) Carbon deposit on the burner blocks:

This problem is more pronounced when the fuel used is furnace oil. Unburned carbon deposits on the burner blocks, and over a period of time, sufficient carbon build up takes place. Due to this build up, the flame geometry is impaired and heating efficiency is lowered.

USE OF PROTECTIVE REFRACTORY COATING AND ITS RESULTS

To overcome these problems, the entire refractory lining of the reheating furnace is coated with a special zircon based coating, ESPON-RCP. Coating can withstand heat of up to 1600 deg. C.

A hot rolling mill producing 40,000 tons per annum of TMT bars has reported the following results:

Increased Refractory lining life:

Without coating : 12 months

With ESPON-RCP coat : 21 months

Fuel Consumption:

Without coating : 40 liters per ton

With ESPON-RCP coat : 38 liters per ton

Annual saving : 80,000 liters

Value of annual saving : Rs. 16,00,000

Cost of Refractory coating : Rs. 70,000

Net annual saving : Rs. 15,30,000

Other results include:

Reduction in time required for achieving hot rolling temperature of 1250 deg. C: In many hot rolling mills, billet re-heating furnace is shut down in the evening at end of working shift. Furnace is switched on next morning, at start of working day. It is observed that use of protective refractory coating enabled achieving the required temperature of 1250 deg. C. much faster than the time required to achieve same temperature when refractory is not coated. Reason: High retention of heat in furnace and increased emissivity of heat by the use of protective refractory coating. In best cases, approximately 45 minutes to 1 hour of time was saved in achieving temperature of 1250 deg. C. Hence, substantial fuel saving is achieved and hot rolling production can commence faster.

Increased uniformity of heat throughout furnace chamber due to heat retention and better heat emissivity by the use of protective refractory coating

Reduced furnace outer shell temperature by 10 deg. C. to 20 deg. C: All gaps and cracks in refractory lining are sealed off during application of refractory coating. This prevents energy leaks, thereby restricting heat transfer to furnace outer shell. Hence, furnace outer shell temperature is reduced as compared with not coated refractor

Fig.1 and 2 show the condition of the refractory lining and burner blocks before coating and fig. 3 and 4 show their condition after using refractory coating.

Fig.1

Fig.2

Fig.3

Fig.4

SUMMARY

- 70% average reduction in burning loss or mill scale loss and increased yield in hot rolling and hot forging is possible by the use of protective anti-scale coatings. Protecting billets by applying anti-scale coating on them ensures a number of additional benefits like elimination or reduction of operations like grinding, acid pickling, etc., reduced decarburization, prevention of billet welding in furnace and improved surface finish.

- Increase in refractory lining life, reduction in fuel consumption and reduction in furnace maintenance downtime are achieved by the use of refractory protective coatings.

STEEL PLANT SPECIALITIES LLP

211, Raikar Chambers, Govandi East, Mumbai-400088. India.

Tel.: 91 22 67978060 Fax : 91 22 25552459

E-mail: info@steelplantspecialities.com

Website: www.steelplantspecialities.com