Anti Scale Protective Coatings

- Home

- Anti Scale Protective Coating

Products

- Substantially reduce scaling on billets / ingots during heating for hot forging or hot rolling. Prevent billet sticking during induction heating.

- Control decarburisation, prevent billet welding in hot rolling, prevent quench cracking.

- Prevent scaling during heat treatment. Prevent rejections, reduce shot blasting / acid pickling operations.

- Prevent scaling during re-heat treatment of finish-machined parts.

- Reduce alpha-case formation and retain heat during hot forging / heat treatment of Titanium, Inconel and such critical super-alloys.

- Substantially reduce scaling on billets / ingots during heating for hot forging or hot rolling. Prevent billet sticking during induction heating.

- Control decarburisation, prevent billet welding in hot rolling, prevent quench cracking.

- Prevent scaling during heat treatment. Prevent rejections, reduce shot blasting / acid pickling operations.

- Prevent scaling during re-heat treatment of finish-machined parts.

- Reduce alpha-case formation and retain heat during hot forging / heat treatment of Titanium, Inconel and such critical super-alloys.

Scaling and decarburisation: Causes and problems due to them

Billets and ingots of metal are heated to high temperatures for further processes like hot rolling and hot forging.

When oxygen combines with metal at high temperatures, scaling / oxidation and decarburisation occur on billets and ingots. Between 1% up to 8% of metal is lost due to scaling at high temperatures. Apart from material loss, scaling causes a number of issues like bad surface finish due to pit marks, reduced forging die life due to impact of hard scale on die during closed die forging, and mill skid situation in hot rolling.

Scale fallen in furnace damage the hearth of furnace and also the induction heater refractory and coils. Removal of scale from the furnace, rolling mill or induction heater is an unproductive, labour intensive work.

Decarburisation occurring at high temperatures leaves the metal unfit for making critical components like rails, sensitive automotive parts like leaf-springs, etc., where decarburisation needs to be maintained as low as possible.

Benefits of ESPON-HR Anti Scale Protective Coating:

After forming, the forged, cast or rolled components need to be heat-treated. During heat treatment, scaling causes problems of pit marks, poor surface finish, non-uniform heating and increased shot-blasting / acid pickling time due to heavy scaling.

Use of ESPON anti-scale protective coatings manufactured by Steel Plant Specialities LLP ensures that scaling is prevented or substantially reduced.

During hot rolling of expensive grades of steel such as stainless steel and alloy steels, a 50% reduction in total scale loss on ingots or billets is ensured. This leads to substantial savings due to increased yield. Decarburisation level can be consistently controlled in hot rolling and hot forging. During heat treatment, ESPON protective anti-scale coatings have often achieved zero scaling. However, results vary depending on various technical factors. Substantially reduced scaling during heat treatment leads to improved surface finish, reduced shot blasting time, reduced rejections and reduced quench cracking.

A range of ESPON brand protective coatings are manufactured by M/s. Steel Plant Specialities LLP as per specific technical requirements of preventing scaling and decarburisation in hot rolling, hot forging and heat-treatment operations. Some of the popular ESPON protective coatings and their applications are given below:

ESPON-HR Anti Scale Protective Coating for billets and ingots during hot rolling and hot forging

ESPON-HR is a protective coating that substantially reduces scaling on billets and ingots during heating prior to hot rolling and hot forging. Sometimes, during heating of billets in pusher-type furnaces, they get stuck to each other at high temperatures. This is also observed during induction heating of billets for hot forging. Coating only the contact surfaces of two billets with ESPON-HR has proven to prevent the problem of billet sticking. ESPON-HR anti-scale protective coating can be applied by brushing, spraying or dipping. Use of ESPON-HR Anti Scale Protective Coating ensures better surface finish of hot rolled or hot forged components. This coating has no impact on heating time or temperature of billets or ingots. Coating gets removed during hot rolling or hot forging operations. ESPON-HR is non-flammable and non-hazardous.

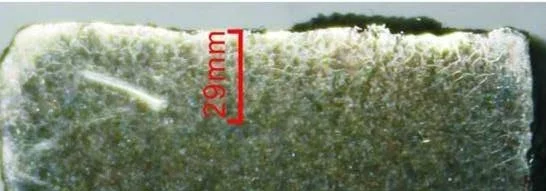

Ni steel billet induction heated to 1230 deg. C. Lot of sticky scale

generated on billet.

ESPON coated Ni steel billet, induction heated to 1230 deg. C. Very minimal scale is generated on billet.

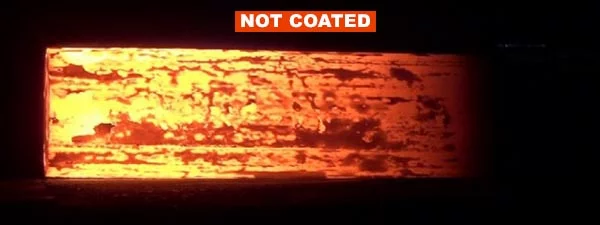

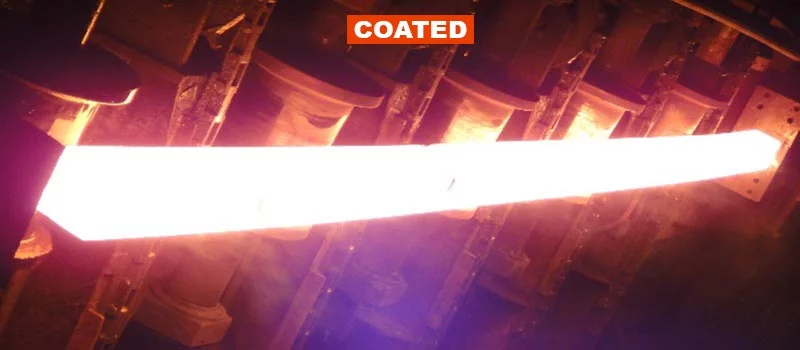

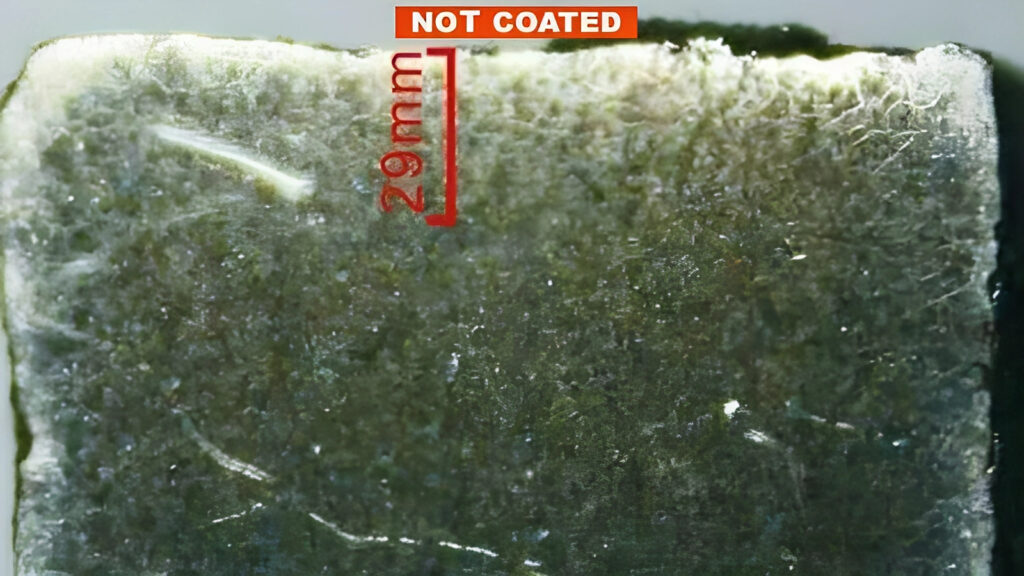

Billet heated to 1250 deg. C. for hot rolling shows substantial scaling.

ESPON coated billet heated to 1250 deg. C. for hot rolling, shows very less scaling.

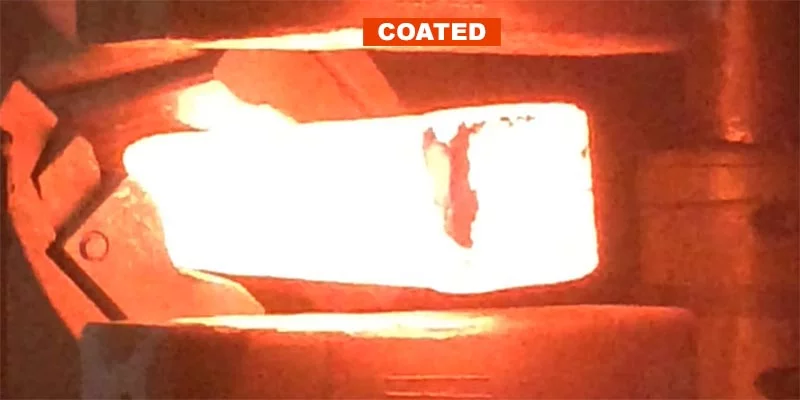

SS ingot heated to 1250 deg. C./ 6 hours soaking in furnace. Total scale loss is approximately 3%

ESPON coated SS ingot heated to 1250 deg. C./ 6 hours soaking in furnace. Scaling reduced by more than 50%

Benefits of ESPON-HR Anti Scale Protective Coating:

- Substantially reduced scaling on billets and ingots during heating for hot forging or hot rolling

- Increased yield

- Helps in avoiding forging rejection due to pit marks formed by scaling.

- Prevents billet sticking or billet welding during heating of billets in furnace or induction heaters prior to hot rolling and hot forging

- Enables better surface finish of hot forged or hot rolled parts

- Reduces unproductive and costly work of scale disposal

- Reduces damage to furnace hearth / floor due to scale deposit

- Can be applied by brushing, spraying or dipping

- ESPON-HR can be used to protect billets or ingots at high temperatures up to 1280 deg. C.

| Packing | : 50 kgs. special HDPE container. |

| Description | : Pink paste free from visible extraneous matter. |

| Weight per litre | : 1.4 kgs ± 0.1 kg. |

| Flash Point | : Nil. Does not catch fire. |

| Safety | : Non hazardous. Non flammable. Non toxic during storage or use. |

| Shelf Life | : 9 months in factory sealed condition. |

ESPON-HR Anti Scale Protective Coating for billets and ingots during hot rolling and hot forging

ESPON-HR is a protective coating that substantially reduces scaling on billets and ingots during heating prior to hot rolling and hot forging. Sometimes, during heating of billets in pusher-type furnaces, they get stuck to each other at high temperatures. This is also observed during induction heating of billets for hot forging. Coating only the contact surfaces of two billets with ESPON-HR has proven to prevent the problem of billet sticking. ESPON-HR anti-scale protective coating can be applied by brushing, spraying or dipping. Use of ESPON-HR Anti Scale Protective Coating ensures better surface finish of hot rolled or hot forged components. This coating has no impact on heating time or temperature of billets or ingots. Coating gets removed during hot rolling or hot forging operations. ESPON-HR is non-flammable and non-hazardous.

Benefits of ESPON-HF Anti Scale Protective Coating:

- Controls decarburisation and ensures that it is at minimum level

- Substantially reduces scaling on billets and ingots during heating for hot forging or hot rolling

- Prevents quench cracking

- Can be applied by brushing, spraying or dipping

- Avoids forging rejection due to scale pits

- ESPON-HF can be used to protect billets or ingots at high temperatures up to 1280 deg. C

ESPON-AS Anti Scale Protective Coating for preventing scaling on forged or cast parts during heat treatment.

ESPON-AS protective coating prevents or reduces scaling on forged and cast parts during heat treatment. This results in reduced grinding and shot blasting time, reduced acid pickling time and preventing rejections due to excessive scaling. Complex profiles like grooves and internal diameter of spindles require excessive shot blasting time and manual grinding to remove scaling. ESPON-AS anti-scale protective coating can be applied by brushing, spraying or dipping in such locations to prevent scaling and substantially reduce shot blasting time. This coating has no impact on heating time or temperature or properties after heat treatment of coated parts. Coating gets removed during hot quenching and subsequent shot blasting or machining operations. ESPON-AS is non-flammable and non-hazardous.

Benefits of ESPON-AS Anti Scale Protective Coating:

- Prevents or substantially reduces scaling during heat treatment

- Reduces non-value adding operations like shot blasting / acid pickling / grinding to remove scaling

- Can be applied by brushing, spraying or dipping

- Avoids forging rejection due to scale pits

- Coating gets removed partly during quenching and completely during shot blasting or machining operations

- ESPON-HF can be used to protect parts at heat treatment temperatures up to 1100 deg. C

ESPON-SR Anti Scale Protective Coating for preventing scaling on machined parts during re-heat-treatment.

Due to metallurgical reasons, heat treated and machined parts may sometimes need to be re-heat-treated. In such cases, there is little or no allowance for scaling. Even a small amount of scaling will cause rejections. Shot blasting or grinding is not possible. In such cases, ESPON-SR protective coating is used to prevent scaling on parts during re-heat treatment. This results in prevention of scaling and prevention of rejections due to scaling. ESPON-SR anti-scale protective coating can be applied by brushing, spraying or dipping. This coating has no impact on heating time or temperature or properties after re-heat treatment of coated parts. Coating has to be removed manualy by light buffing or such processes. ESPON-SR is non-flammable and non-hazardous.

Benefits of ESPON-SR Anti Scale Protective Coating:

- Prevents scaling on machined parts during re-heat treatment

- Can be applied by brushing, spraying or dipping

- Coating must be removed by light buffing or emery paper brushing or such processes

- ESPON-SR can be used to protect parts at re-heat treatment temperatures up to 1050 deg. C

ESPON-ACR Protective Coating for heat retention in titanium billets and reducing alpha-case formation.

During heating of titanium, Inconel and such highly critical super alloys, much care is required to ensure that forging is done at precisely controlled temperature. In the case of titanium forging, heat is lost very fast from heated billets, thereby making subsequent processing like forging very difficult. Heat loss from titanium billets can cause rejection due to required properties not being met. Additionally, similar to oxidation and decarburisation in steels, titanium is prone to formation of alpha-case on the surface during heating at high temperatures. Alpha case formation in titanium causes rejection of parts during final testing. Hence, alpha case formed on titanium must be removed by grinding after forming the parts. Alpha case removal is a laborious process as hard titanium is not easily machinable. Hence, before heating, titanium must be protected with ESPON-ACR protective coating. This results in retention of heat in heated titanium billets so that forging or such processing can be carried out as planned. Alpha case formation on titanium is substantially reduced by the use of ESPON-ACR protective coating. ESPON-ACR protective coating can be applied by brushing, spraying or dipping. This coating has no impact on heating time or temperature or properties after heating of coated parts. ESPON-ACR is non-flammable and non-hazardous.

Benefits of ESPON-ACR Protective Coating on Titanium:

- Retains heat in heated titanium billets

- Substantially reduces formation of alpha case on heated titanium parts

- Increases yield. Saves expensive titanium material from loss due to alpha case formation

ESPON-ACR can be used to protect titanium at heating temperatures up to 1260 deg. C