Anti-Nitriding Stop-off Paste

- Home

- Anti-Nitriding Stop-off Paste

Stop-Off Paste for Preventing Nitriding during Gas Nitriding and Plasma Ion Nitriding

Gas Nitriding and Plasma Ion Nitriding are case hardening processes. They improve wear resistance, seizing resistance, corrosion resistance and fatigue life of nitrided parts. Quite often, selective gas nitriding or selective plasma-ion nitriding becomes necessary. ESPON anti-nitriding stop off pastes are very useful in preventing nitriding on the coated areas

Plastic injection moulding machinery parts like barrel screws are nitrided for increasing their wear resistance. However, threaded areas will become brittle if they are nitrided / hardened. ESPON anti-nitriding stop-off paste is used to mask or protect such areas from nitriding.

Hot forging dies are nitrided to increase their service life. However, during die sinking, machining of fully nitrided forging dies is very time consuming due to their high hardness. Expensive machine[1]tools wear out fast when used for machining such nitrided dies. Hence, time and money are lost during machining of nitrided dies

An effective way to solve this problem is by carrying out selective nitriding, only on the impression of the die, where the hardness is required. Remaining portion of the die is coated with ESPON anti-nitriding stop-off paste before charging dies into nitriding furnace. Hence, ESPON coated areas of die will be protected from nitriding. Hardness will be achieved only on not coated die impression during nitriding. Nitriding increases forging die life and preventing nitriding using ESPON coating enables easy machinability of forging die during die sinking.

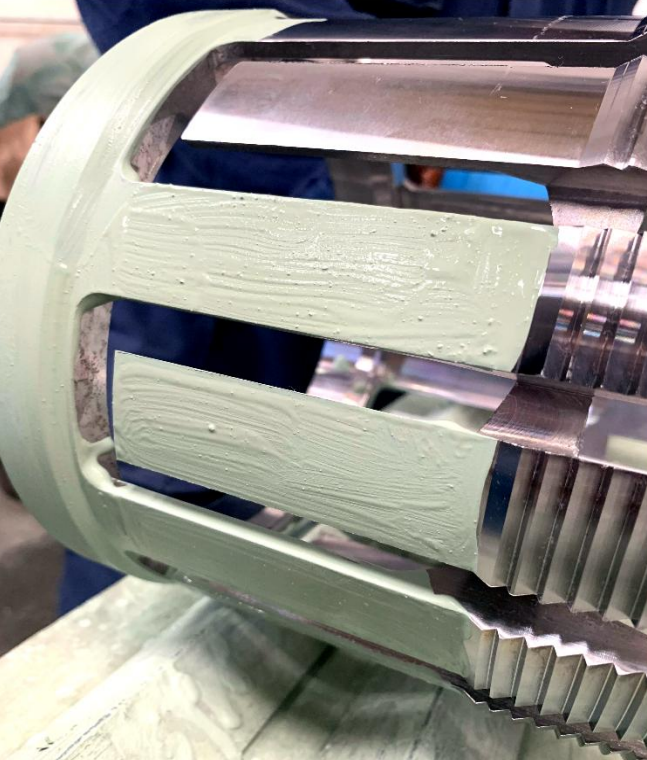

Parts coated with ESPON Anti-Nitriding Stop-Off Paste

Parts coated with ESPON Anti-Nitriding Stop-Off Paste

Hence, use of ESPON anti-nitriding stop-off pastes have proven to increase productivity and reduce costs by reducing machining time substantially and increasing machine tool life.

A range of ESPON brand anti-nitriding stop-off pastes are manufactured by M/s. Steel Plant Specialities LLP as per specific technical requirements of preventing nitriding in gas nitriding and plasma ion nitriding processes.

Some of the popular ESPON anti-nitriding stop-off pastes and their specifications are given below:

| Grade Standard | Technical Grade |

| Physical State | Paste |

| Usage/Application | Industrial |

| Applicable Industry | Gas nitriding operations |

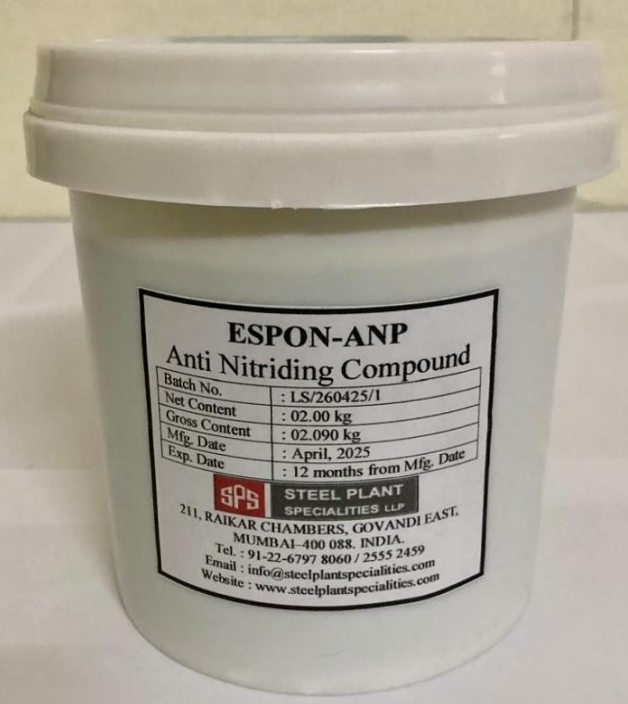

| Description | Light green colored paste, free from visible extraneous matter |

| Packaging Type | Special HDPE container |

| Packaging Size | 1kg / 2kgs. special HDPE container. |

| Flash Point | Does not Flash. Does not catch fire. |

| Safety | Non-flammable and non-hazardous during storage and use. |

| Country of Origin | Made in India |

ESPON-ANP Anti-Nitriding Stop-Off Paste

ESPON-INT3 Anti-Nitriding Stop-Off Paste

| Grade Standard | Technical Grade |

| Physical State | Paste |

| Usage/Application | Industrial |

| Applicable Industry | Plasma ion nitriding operations |

| Description | Yellow colored paste, free from visible extraneous matter |

| Packaging Type | Special HDPE container |

| Packaging Size | 1kg / 2kgs. special HDPE container. |

| Flash Point | Does not Flash. Does not catch fire. |

| Safety | Non-flammable and non-hazardous during storage and use. |

| Country of Origin | Made in India |

How it Works:

- The paste is applied to the areas that are to be prevented from nitriding.

- During the nitriding process, the paste forms a barrier, preventing nitrogen atoms from penetrating into the metal surface.

- This prevents case hardening in the coated areas, allowing for selective nitriding only where desired.

Benefits of using ESPON Anti-nitriding stop-off paste:

1. Precise Control:

Enables selective nitriding, ensuring hardness is prevented in coated areas.

2. Reduced Machining Time:

By preventing unwanted hardening, it reduces time required for machining the nitride parts.

3. Increased Tool Life:

Selective nitriding can enhance tool life by preventing unwanted hardening in undesired areas.

4. Cost Savings:

By optimizing the nitriding process, it can lead to cost savings in machining and overall manufacturing.

5. Selective Nitriding:

Allows for precise control of case hardening, preventing it on coated areas while hardening other areas.

6. Easy Application:

The paste can be applied by brushing, spraying, or dipping.

7. Non-flammable and Non-hazardous:

ESPON coating is non-flammable and non-hazardous during storage and use